Prepare for E-commerce Supply Chain Disruptions: Port Congestion in 2025

E-commerce supply chain disruptions are expected to worsen due to port congestion by Q3 2025, necessitating proactive strategies such as diversifying suppliers, leveraging technology for real-time visibility, and optimizing inventory management to mitigate potential impacts on businesses.

The looming threat of e-commerce supply chain disruptions, particularly with port congestion expected to worsen by Q3 2025, demands immediate attention. Is your business prepared for the potential chaos? It’s time to take a hard look at your strategies and implement proactive measures to mitigate the impact.

E-commerce Supply Chain Outlook: A Storm on the Horizon

The global e-commerce landscape is facing a significant challenge: increasing e-commerce supply chain disruptions. Experts predict that port congestion will reach critical levels by Q3 2025, threatening to cripple businesses that rely on timely and efficient supply chains. Understanding the factors contributing to this crisis is the first step toward preparing your business.

The Perfect Storm: Factors Driving Port Congestion

Several converging factors are contributing to the predicted surge in port congestion. Increased consumer demand, labor shortages, and infrastructure limitations are creating a bottleneck that is expected to intensify in the coming months.

- Increased consumer spending: The continued growth of e-commerce is placing unprecedented strain on existing supply chain infrastructure.

- Labor shortages: A lack of available workers at ports and in related industries is slowing down the movement of goods.

- Infrastructure limitations: Many ports lack the capacity to handle the current volume of shipments, leading to delays and congestion.

Ignoring these factors will lead to inevitable delays and increased costs. Proactive strategies are crucial to navigate this challenging environment effectively.

Mitigating the Impact: Diversifying Your Supplier Base

One of the most effective strategies to mitigate the impact of e-commerce supply chain disruptions is to diversify your supplier base. Relying on a single supplier can leave your business vulnerable to unforeseen disruptions. Spreading your risk across multiple suppliers provides a buffer against potential delays and shortages.

Why Supplier Diversification is Crucial

Diversifying your supplier network means exploring alternative sources for your products and materials. This reduces your dependence on any single point of failure and provides greater flexibility in responding to disruptions.

- Reduced reliance on single suppliers: Spreading your risk across multiple sources minimizes the impact of any one supplier’s challenges.

- Increased negotiation power: Having multiple suppliers allows you to negotiate better terms and pricing.

- Greater flexibility: A diverse supplier base allows you to quickly adapt to changing market conditions and demand fluctuations.

Building a diversified supplier network requires careful planning and due diligence. It’s essential to thoroughly vet potential suppliers and establish strong relationships to ensure reliability and quality.

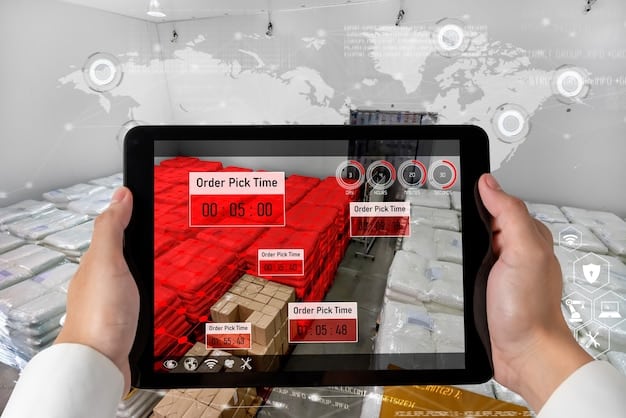

Embracing Technology: Leveraging Real-Time Visibility

In today’s interconnected world, real-time visibility into your supply chain is no longer a luxury but a necessity. Technology enables you to track your goods from origin to destination, identify potential bottlenecks, and proactively address issues before they escalate.

Implementing advanced tracking systems offers key advantages:

- End-to-end tracking: Monitor your goods seamlessly from manufacturing to delivery.

- Early issue detection: Identify potential delays or disruptions in real-time.

- Informed decision-making: Make proactive decisions based on up-to-the-minute data.

Optimizing Inventory Management: Preparing for Uncertainty

Effective inventory management is critical to weathering the storm of e-commerce supply chain disruptions. By optimizing your inventory levels, you can minimize the risk of stockouts while avoiding the costs associated with excess inventory.

Strategies for Smarter Inventory Management

Adopting a data-driven approach to inventory management can help you anticipate demand fluctuations and adjust your stock levels accordingly. This requires a combination of forecasting techniques, safety stock planning, and strategic buffer inventory.

Implementing effective strategies offers key advantages:

- Accurate Demand Forecasting: Anticipate future demand with statistical tools.

- Safety Stock Planning: Establish safety stock levels to reduce risk.

- Strategic stock: Maintain stock to avoid shortages while optimizing costs.

Strengthening Logistics Partnerships: Building Resilient Networks

Logistics partners play a crucial role in ensuring the smooth flow of goods through your supply chain. Building strong relationships with your carriers, freight forwarders, and warehouse providers can enhance your resilience and responsiveness in the face of disruptions. It can mitigate e-commerce supply chain disruptions when properly implemented.

Why Strong Partnerships Matter

Collaborating closely with your logistics partners allows you to gain access to their expertise, resources, and networks. This can help you navigate complex challenges and find creative solutions to minimize disruptions.

Collaborating closely offers great advantages:

- Expertise and resources: Access their knowledge and extensive resources,

- Solutions to minimize disruptions: Find creative solutions to solve complex challenges,

- Faster Response Times: Enabling quick adaptation to supply chain problems,

Supply Chain Visibility: The Key to E-commerce Success

Achieving end-to-end **e-commerce supply chain disruptions** visibility is the ultimate strategy for mitigating risk and ensuring business continuity. By integrating data from all stages of your supply chain, you can gain a holistic view of your operations and identify potential vulnerabilities before they impact your bottom line.

Building a Transparent Supply Chain

Creating a transparent supply chain requires the adoption of advanced technologies, such as blockchain, IoT sensors, and cloud-based platforms. These tools enable you to track your goods in real-time, monitor environmental conditions, and verify the authenticity of your products.

| Key Aspect | Brief Description |

|---|---|

| 🚚 Supplier Diversification | Reduces risk by sourcing from multiple suppliers. |

| 📊 Real-Time Visibility | Tracks goods to identify and address bottlenecks proactively. |

| 📦 Inventory Optimization | Minimizes stockouts and excess inventory costs. |

| 🤝 Logistics Partnership | Enhance resilience and response. |

FAQ Section

▼

The congestion is driven by increased e-commerce demand, labor shortages, and infrastructure limitations, creating bottlenecks that will impact supply chains significantly.

▼

Diversifying suppliers reduces dependence on a single source, providing resilience against delays, shortages, and other potential issues caused by disruptions.

▼

Technologies like blockchain, IoT sensors, and cloud-based platforms enable tracking goods in real-time, monitoring conditions, and verifying product authenticity throughout the supply chain.

▼

Optimized inventory minimizes stockouts and excess inventory costs by accurately forecasting demand and setting strategic safety stock levels to buffer against uncertainties.

▼

Strong partnerships with carriers, freight forwarders, and warehouse providers provide access to expertise, resources, and solutions that help navigate complexities and minimize the impact of disruptions.

Conclusion

Preparing for potential **e-commerce supply chain disruptions** due to port congestion expected by Q3 2025 requires proactive measures. By diversifying suppliers, embracing technology for real-time visibility, optimizing inventory management, and strengthening logistics partnerships, businesses can build resilient networks capable of weathering the storm and ensuring continuity.